Flowstate’s Background Digital Leak Simulator

How do you know the leak detection system you implemented months – or years – ago is still working?

Does it still have the same sensitivity it did when it was commissioned?

Initial testing is conducted to verify that a system achieves it expected performance. A number of tests may be done at that time to evaluate the system under varying operating conditions (ref API RP 1130). But how do you have assurance the system continues to perform as expected after it is in service? Indeed, at last fall’s PIX/LEPA (Pipeline Information eXchange / Liquid Energy Pipeline Association) meeting, participants discussed interest in a new standard metric to address this. Current industry guidance describes four performance metrics of Sensitivity, Accuracy, Reliability and Robustness to establish performance targets for a system. But a new metric of “Assurance” was proposed to highlight the efforts necessary to continually verify that a system continues to perform and does not degrade.

There are a couple ways that Flowstate has equipped the LDS to meet this need:

- The Flowstate LDS comes with an accompanying tool called the Segment Health Monitor to continuously monitor key performance indicators. (More about that in a separate article.)

- The LDS also includes a built-in digital leak simulator that can impose a leak condition of a specified size to test the sensitivity of the system.

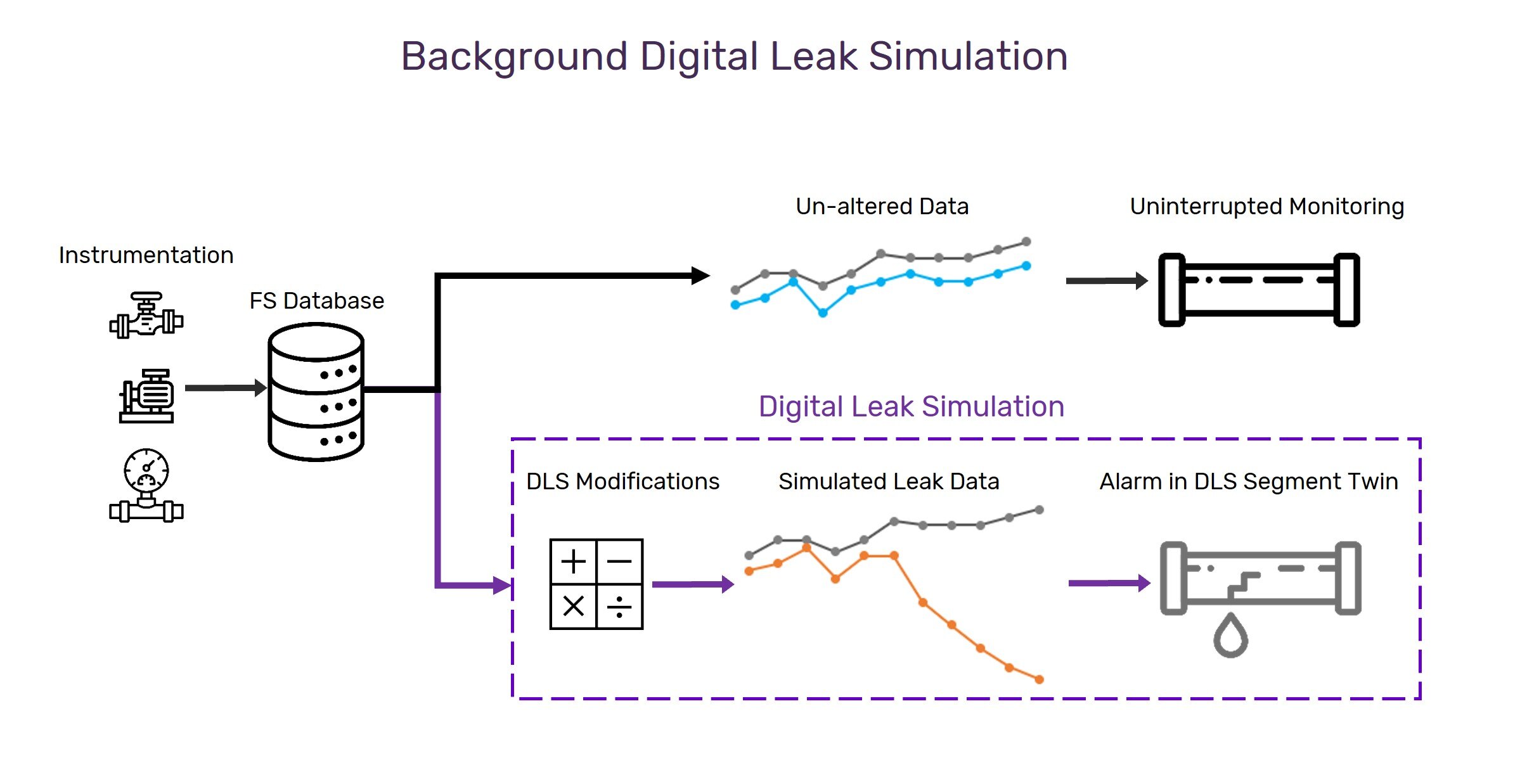

Digital Leak Simulation

Flowstate utilizes digital leak simulation capabilities to validate performance during the model development process and for system acceptance testing purposes (commissioning, change verification, etc.). The simulation uses mathematical operations to modify a pipeline’s real-time measurement data and simulate the physical response (drops and surges) typically experienced during a leak condition.

This DLS functionality is available on demand in the LDS to use when you need to do required periodic retesting or to conduct a verification test after a change is implemented. But even these activities are infrequent. Assurance would be better attained if the system was continuously tested for leaks of different sizes, throughout operational schedules.

For this purpose, Flowstate offers Background Digital Leak Simulation (BDLS).

With the Flowstate LDS, when a segment is supplied with a leak detection suite, it is also equipped with a set of tests designed to continuously monitor model performance. Tests of different leak sizes are set up to run periodically through normal operations, repeatedly testing the sensitivity of the system. Segments with BDLS are constantly tested for their performance on simulated leaks of all sizes to ensure both target leak size and time to detection remain within target bounds. These tests take place entirely in the background of the application and do not cause unnecessary alerts for controllers to manage or modify any operational data.

Performance in these BDLS tests is monitored by the Segment Health Monitoring tool (SHM). If detection rates dip below an acceptable threshold, the SHM tool serves as an early warning system, alerting us to performance degradation of the leak detection models on a segment. This proactive notification empowers us to react swiftly and effectively, preventing loss of system sensitivity.

Performance can also be monitored and explored in our accompanying analysis tool PipeIntel, allowing for exploration of test data. The following shows an example of repeated tests of a simulated 34 bph leak over the course of 24 hrs. The bottom graph shows flow rates on the segment, including several small injections. The yellow bars in the middle graph show the occurrence of leak simulations. Finally, the top graphs plots the calculated "imbalance" and shows the leak detection response. The purple shows leak monitoring and the red shows leak alarm status has been reached. It can be seen that one test reach 90% of alarm status before the test ended.

Pipeline operating conditions seldom remain constant. Changes to a line – such as shifts in meter offset or addition of an injection that is not accounted for – may reduce the sensitivity of the system. Consequently, leak detection models may overlook leaks they were originally designed to detect. This is why it is imperative to continually assess the performance of leak detection models.

Leak detection software isn't just about short-term solutions; it's about ensuring the long-term security of pipeline infrastructure. By continually monitoring the performance of our systems, we provide operators with assurance and peace of mind, knowing that the reliability of their leak detection is being constantly monitored.

Comments

Add Comment