In October 2019, the Pipeline and Hazardous Materials Safety Administration (PHMSA) issued final rules amending the Pipeline Safety Regulations. The revised Liquid Pipeline Rule (CFR 49 Part 195) extended the requirement for leak detection systems beyond high-consequence areas to include all regulated, non-gathering hazardous liquid lines. The new rule also included a timeline for implementation. All newly constructed pipelines must comply with the rule upon commissioning, and all existing pipelines were given 5 years to comply – a grace period which ends October 2024.

For many operators, this will mean adding or improving leak detection on existing systems. It will also mean becoming familiar with other leak detection requirements or guidelines in the regulation.

What is in the Rule?

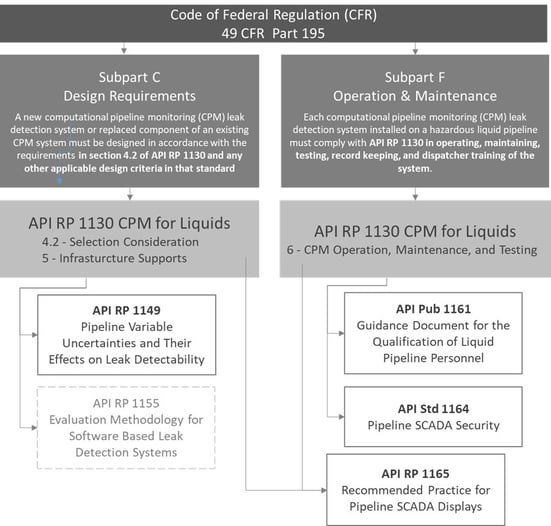

With regards to leak detection, there are 4 key sections in the rule. They are illustrated/summarized in the image and discussed below.

Ok, so what is really in there?

I’ve summarized my takeaways in the green band at the bottom, but here’s a little more detail:

Which Pipelines?

The 2019 final rules extended the required use of leak detection systems beyond high consequence areas (HCAs) to all regulated, hazardous liquid pipelines. A couple notes:

- Section 195.1 of the regulation includes a complicated list of types of lines that are covered and those that are exempted, but it really boils down to the above.

- Although regulated rural gathering lines are covered by the rule, they are exempted from the implementation timeline included in Subpart C and described below (ref 195.134 d)

- Note that 195.452 on HCA's requires that all pipelines in an HCA must have a means to detect leaks.

Design Requirements

There are two key elements in regarding leak detection in Section 195.134pipeline Design Requirements.

- Due dates for having leak detection in place – The Safety Act identified that leak detection needed to be in place, but industry feedback noted that retrofitting would take time. In response, new lines (built after Oct 2019) were essentially required to have leak detection in place at their start and existing lines (built prior to Oct 2019) were given 5 years to comply. As such, two deadlines were given:

- New lines – October 1, 2020

- Existing lines – October 1, 2024

It is later noted that these deadlines do not apply to offshore gathering or regulated rural gathering lines.

- Design Guidance – Prior to this rulemaking, the regulation had – by congressional mandate - established a leak detection standard. It did this by incorporating portions of API RP 1130 which included several ‘recommended’ considerations and guidelines for selection and implementation of a CPM system. Included in there is a list of features or functionality that CPM system might have as well as recommended performance metrics.

195.134 of the reg then states that new or replaced CPM systems must be designed in accordance with the requirements in section 4.2 of API RP 1130 and any other applicable design criteria in that standard.

Some notes:

- The list in 2 Selection Consideration are “mays”. It is a laundry list of things that could be included but not necessarily required. Many of the items are not needed for all methods of leak detection. These are essentially requirements on the solution provider.

- It is also good to be familiar with Section 4.2.1 Performance Metrics which describes four metrics that are commonly referred to in leak detection: Reliability, Sensitivity, Accuracy, and Robustness. While it is the solution provider that should meet these performance metrics, it really is the operator that should be defining the performance targets.

- What is included with “any other applicable design criteria”? Yes, that is a little ambiguous for a “must be designed IAW” regulation. There are several other design considerations peppered throughout the RP such as recommendations for HMI best practices, data collection, etc.

- If you aren’t familiar with the different kinds or methods of internal leak detection, you might check out some of the definitions included in the document. Keep in mind these are not inclusive of some recently developed technologies.

- There are other standards referenced within API RP 1130. These are illustrated here.

Operations & Maintenance

195.444 has two key elements.

- An affected pipeline “must have an effective system for detecting leaks” that complies with the design requirements above or has met the requirements of leak detection later stipulated for High Consequence Areas (see below) and states that operator much evaluate the capability of their system.

- Again, in establishing leak detection standards, this section invokes Section 6 of API RP 1130 which provides some guidance for “operating, maintaining, testing, record keeping, and dispatcher training of the system”. This includes requirements for testing, training, documentation, alarming, etc.

High Consequence Areas

195.452 specifies requirements for integrity management (IM) for HCAs. It is a lengthy section, but with regards to leak detection is states that operators must:

- Identify preventive and mitigative measures to protect the HCA

- This must include a means to detect leaks that has been evaluated and determined to be capable of protecting the HCA.

- This evaluation and the decisions made must be documented.

In Summary

If you have a hazardous liquid pipeline in an HCA or is regulated (not regulated rural) and you do not have an API RP 1130-aligned leak detection system in place, you will want to take a look at those requirements. Soon.

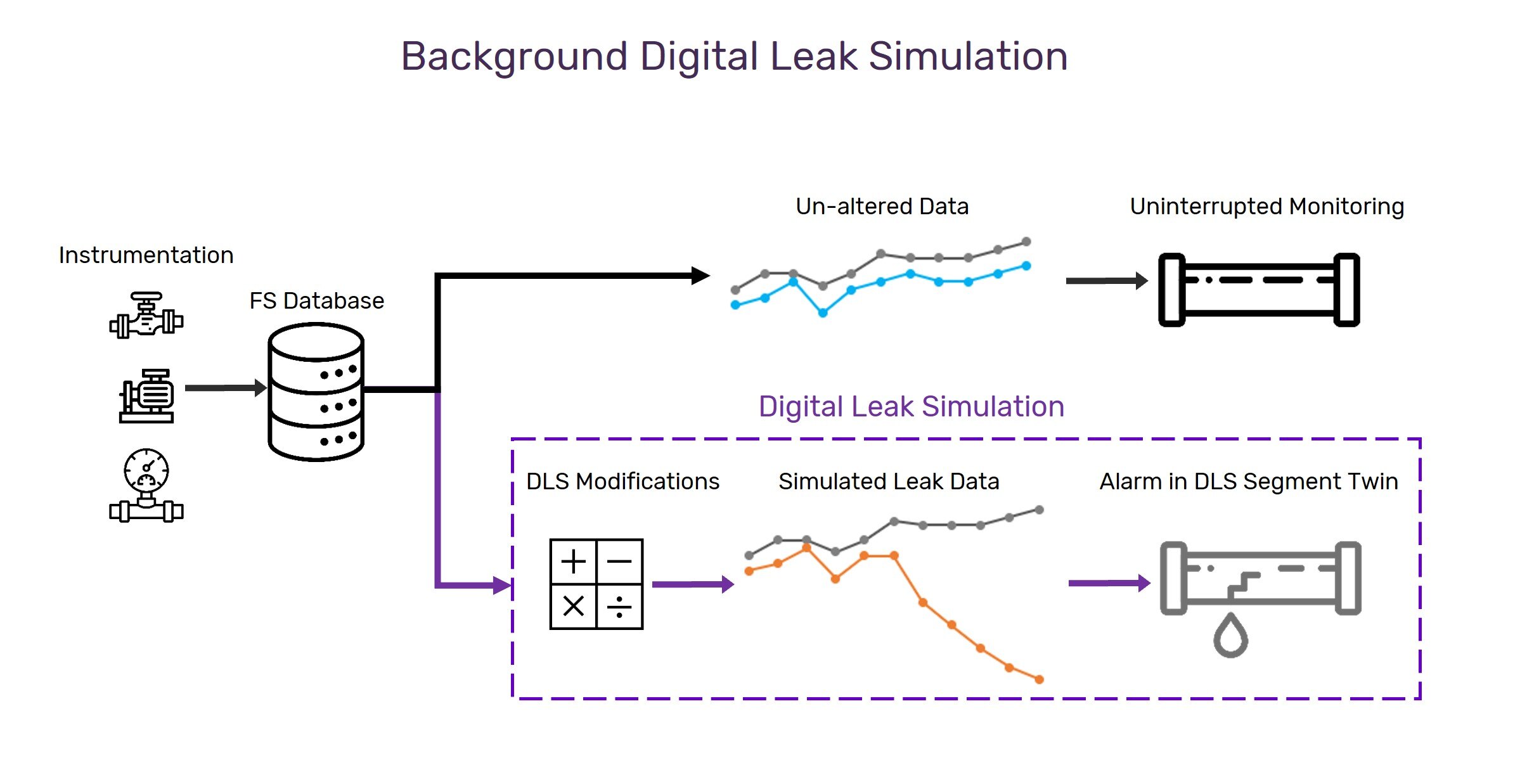

In coming posts, I will highlight some further discussion of API RP 1130 and the Liquid Pipeline Rule as well as some work that Flowstate has done to provide operators with insights on those leak detection performance metrics mentioned above.

Disclaimer:

These are some general thoughts and highlights related to leak detection requirements in CFR Title 49 Part 195. However, it is important to note that the regulation is comprehensive and contains additional details and specific requirements that operators must comply with. For more detailed and up-to-date information, it is recommended to refer directly to CFR Title 49 Part 195 or consult with legal or regulatory experts familiar with pipeline safety regulations.

Comments

Add Comment